Located on the edge of Columbia near the banks of the Susquehanna River hidden in the brush is the abandoned ruins of the St. Charles Furnace. While you can safely climb inside the structure today, things would have been very different 150 years ago when the internal temperature ranged between 1,600 and 2,300°F.

Built-in 1854, the St. Charles Furnace had an estimated 10,000 ton per year pig iron production capacity. Pig iron is the first metallic product after the reduction of iron ore. Full of impurities and brittle, pig iron is almost always further refined into steel or cast iron.

Pig iron gets its name from the way it looks when being made. Workers would construct sand molds in a branching structure for making ingots. When molten metal was poured in, it resembled a litter of piglets being suckled by a sow.

The St. Charles Furnace was built by Clement Brooke Grubb, an ironmaster from the prominent Grubb iron mining and manufacturing family. So famous, in fact, that he has numerous Lancaster County locations named after him, including a small stream called Grubb Run in Shenks Ferry. Visit it for yourself while hunting treasure in Bausman’s Hollow. Click here to learn how.

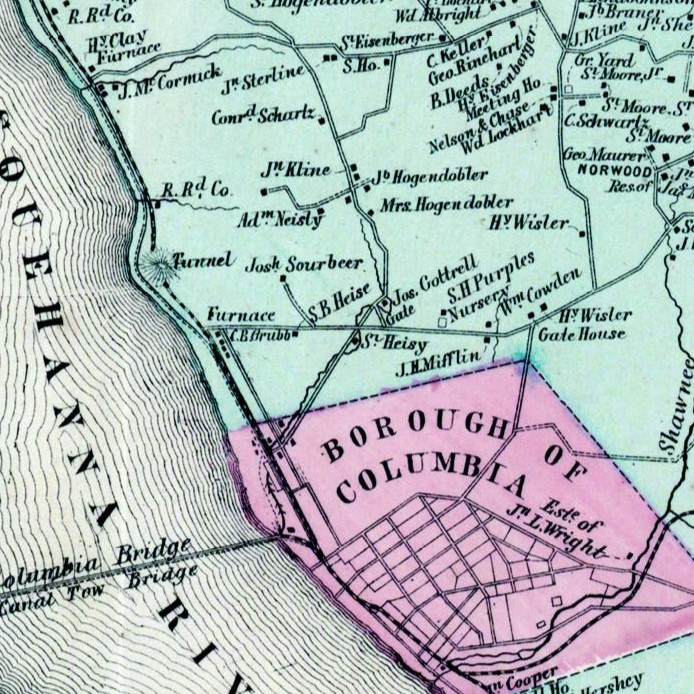

The furnace was located near the Pennsylvania Railroad for easy transportation. See the map below. Today the path is known as the Northwest Lancaster County River Trail that travels from Columbia to Bainbridge.

Years later, in 1875, Grubb and his son Charles bought the Henry Clay Furnace (also visible on the map above) located one mile upstream at a point once known as Kelley’s Tavern. After purchasing it, the furnace was renamed St. Charles No. 2. The combined power of these two anthracite fueled furnaces had an annual capacity of over 20,000 tons of pig iron.

The complex was well known for its quality for boilerplate, bars, nails, and foundry work. In 1863, Grubb built a large iron ore roaster, the first of its kind in Lancaster County, to remove sulfur from the local ores used in the furnaces.

The St. Charles Furnace was remodeled in 1879-80, but only six years later, it went out of blast for the last time and was finally dismantled in 1897.

The square stack support and stone walls of the ore roaster building still remain along the Northwest Lancaster County River Trail.

St. Charles Furnace States

Lifespan: 32 years from 1854 to 1886 all in Grubb family

Furnace type: Anthracite hot blast

Ore source: Local ore & Codorus Iron Mine

Production: Estimated 10,000 ton/year

Transportation: Pennsylvania Canal and Pennsylvania Railroad

Planning Your Visit

You can visit the St. Charles Furnace on foot or via bike along the Northwest Lancaster County River Trail. You can leave your vehicle at the Northwest River Trail parking lot. Here’s a link to the location. From there, it is a short .7 mile walk along a paved path to the furnace. Click here for walking directions.

Gallery

3 thoughts on “Some like it hot. Step inside the cold heart of Columbia’s St. Charles Furnace”

Comments are closed.